Home & Garden

Home & Garden

Tools

Tools

Bolts and screws

Bolts and screws

Don's Home

Home & Garden

Home & Garden

Tools

Tools

Bolts and screws

Bolts and screws

|

| Fastener Types | Wood Screws | Pipes | Drill sizes | Tap sizes | |

Under Construction

Contents: Class & Grade | Type (fasteners) | Terms | Standards | Torque Notes | Bolt Sizes | Tap Drill Required | Drill Size | Lubrication | wrench sizes |Links

Grade Markings: See bolt size below. Bolt Class and Grade (Torque specs vary - numbers below are at high end.)

tpi - Threads per inch C.P. - Commerciallly Pure HT - Hardened and Tempered Temp. - Quenched and Tempered Metal Properties See other terms below † - Strength: pounds per square inch (psi)(English unit) or in Megapascal (MPa) (SI unit) MPa - Megapascal = 1 N/mm2 = 145 psi

The number before the point is the ultimate tensile strength in MPa divided by 100. The number after the point is 10 times the ratio of tensile yield strength to ultimate tensile strength. For example, a property class 5.8 bolt has a nominal (minimum) ultimate tensile strength of 500 MPa, and a tensile yield strength of 0.8 times ultimate tensile strength or 0.8(500) = 400 MPa. See table below. Metric System & Specifications.pdf | fastenal.com

The number before the point is the ultimate tensile strength in MPa divided by 100. The number after the point is 10 times the ratio of tensile yield strength to ultimate tensile strength. For example, a property class 5.8 bolt has a nominal (minimum) ultimate tensile strength of 500 MPa, and a tensile yield strength of 0.8 times ultimate tensile strength or 0.8(500) = 400 MPa. Caution is advised when considering the use of property class 12.9 products. The capabilities of the fastener manufacturer, as well as the anticipated service environment, should be carefully considered. Some environments may cause stress corrosion cracking of nonplated, as well as electroplated, products. In the United States, property classes 8.8.3 and 10.9.3 also defined; the "3" after the second decimal point indicates the fastener is made of weathering steel. * Torques are examples. Coatings like crome, cadmium or zinc and lubricants, inculding Loctite (which acts as a lubricant before it dries) will affect the torque required. (higher numbers in above chart are for zinc plated bolts). Torque tables will vary by 10-15%. The MIL-Specs (NAS and MS) are used by the aircraft industry. The above numbers tend to be toward the high end of the ranges. See Torque below for more information and links to torque tables. In the 1980's large numbers of counterfeit bolts appeared in the United States, almost all imports. For this reason, the SAE grade markings can no longer be trusted unless one knows exactly who made and graded the bolt. A stronger bolt may not always be better. In some cases a bolt may be selected to fail at a certain stress to protect a more expensive part.

Bolts are graded, designating how "hard" they are. The "harder" bolt you choose, the higher the grade number, and the more brittle or "less shear resistant" it becomes. Higher grades are not necessairly better depending on the use. The American Society for Testing Materials (ASTM) is one of the organizations which grades fastners in specification documents e.g. A193, A194, A320. Some equivalent grades are:

18-8 Stainless Steel This is the most popular type of stainless used in the production of fasteners. Its composition is approximately 18% Chromium and 8% Nickel, thus the name 18-8. Several grades of stainless are included in this classification including 302, 303, 304 and 305. These all have good strength and corrosion resistance. 316 Stainless Steel This is more corrosion resistant than 18-8, but also more expensive. It is composed of approximately 18% Chromium and 12% Nickel with the addition of 2% to 4% Molybdenum. It also maintains its strength at higher temperatures than 18-8. 410 Stainless Steel It has approximately 12% Chromium with no Nickel. It is not very corrosion resistant and is magnetic, but it can be heat treated to become harder. Alloy 20 This alloy has approximately 20% Chromium and 34% Nickel plus 3% to 4% Molybdenum. It is very corrosion resistant and is especially popular when in contact with sulfuric acid. Brass This metal is approximately 65% Copper and 35% Zinc. It offers a good combination of strength, corrosion resistance and workability. Nickel Copper 400 This alloy is approximately 70% Nickel and 30% Copper. It has excellent strength and corrosion resistance and is used in salt water marine and other chemical environments. Titanium This has a very high strength to weight ratio, as well as good corrosion resistance. Inconel Registered Trademark of Inco Ltd. Composed of approximately 77% Nickel and 15% Chromium. It offers superior strength and good corrosion at high temperatures. Silicon Bronze It is composed of approximately 96% Copper, 3% Silicon, and 1% Manganese. It is more corrosion resistant and tougher than brass. It is widely used in the electrical industry. ISO metric fastener material strength property classes (grades) is specified in ISO Standard 898-1. The 5 in 5.8 means nominal (minimum) tensile ultimate strength is 5 * 100 = 500 MPa (Megapascal); the 8 means the yield strength is 0.8 times tensile ultimate strength or 0.8 * 500 = 400 MPa. 1. - Stainless Steel Tensil strength ranges from 74,000 - 180,000 psi. There are two common types of stainless steel fasteners: corrosion-resistant stainless steel, ASTM 304 (a.k.a. 18-8 †) or DIN/ISO A2, and acid-resistant stainless steel, ASTM 316 or DIN/ISO A4. A2 is by far the most prevalent material, and is what is normally supplied for stainless metric fasteners. † - 18-8 or 18/8 - Means that it contains 18% chromium and 8% nickel. A better grade is 18/10 it provides more corrosion resistance and greater durability. There are three typical property classes (strengths) for in the metric system: 50, 70, and 80. The class equals the tensile strength divided by 10. The metric property class is a dash (-) number after the alloy designator. For example, a screw marked A2-70 is a 304 stainless steel screw with a 700 N/mm2 tensile strength. Both alloys come in all property classes, but A2-70 and A4-80 are the most common.

304 316 384 Austenitic Stainless Steel, Cold Worked 316 stainless steel is a higher alloyed material containing 2-3% molybdenum, which provides improved pitting and crevice corrosion resistant properties, especially in environments containing chlorides.

2. Aluminum 1024-T4 - 1024 specifies Alloy per Aluminum Association series and T4 the temper. 3. AERMET 100 is a martensitic steel super-alloy from ARP that is used for conecting rod bolts in top fuel dragsters.

Terms: (See also standards below) See: High-Strength Structural and High-Strength Low-Alloy Steels

Standards: See Glossaries at: bonaero.com, Defense Logistics Agency

Torque Notes:

Torque and Fastener Matching Information (NAS torques) at Costal Fabrication. Keeping it All Together - The Nuts and Bolts of Bolting Marine Fastners. Recommended Torque Spec's for Titanium Fasteners Torque and Screw Interchangeability at Bondhus. Preloading accuracy

Sliding friction is affected by materials (like steel or aluminum on titanium), surface roughness, bearing area, material hardness, lubrication and so on.

It takes more force to tighten a larger bolt. It takes more force to stretch an SAE Grade 8 bolt than it does to stretch an SAE Grade 5 bolt because of the greater material strength.

Undertorque can result in unnecessary wear of nuts and bolts as well as the parts they hold together. When insufficient pressures are applied, uneven loads will be transmitted throughout the assembly which may result in excessive wear or premature failure due to fatigue.

The basic formula Torque = K x D x P where: Bolt Sizes (inch/SAE to Metric) TPI = Threads per inch

The actual size (Major diameter) is slightly smaller than the Nominal (Basic) size.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Size Conversion

|

|

National Coarse (NC), National Fine (NF), National Extra Fine (NEF), National Special (NS), National 12 Pitch (12N) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dimensions of Heavy Hex Nuts A  A standard hex nut, also referred to as a finished hex nut, has a smaller width across the flats and corners compared to a heavy hex nut, and a heavy hex nut is slightly thicker than a standard hex nut of the same nominal size. In fact, heavy hex nuts are exactly a 1/8” larger across the flats than a standard hex nut in all sizes, requiring a 1/8” larger socket or wrench to install. Also, heavy hex nuts have a higher proof load strength compared to a hex nut according to ASTM A563. Heavy Hex Nuts ASME B18.2.2 used with Stud Bolts according to ASME B16.5

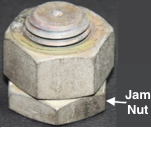

ASME B18.2.2-1987, Square and Hex Nuts (Inch Series) Hex jam nuts are thinner than a standard hex nut but have the same dimension across the flats and corners. Hex jam nuts have two common applications. A jam nut can be threaded onto a bolt and run tight against the standard nut which will lock the nut in place and prevent it from backing off. Jam nuts are sometimes used for leveling purposes as well. Since hot-dip galvanizing typically adds 2.2 to 5 mils of thickness to the threaded portion of a fastener, galvanized hex jam nuts are tapped oversize to compensate for the corrosion resistant coating on the bolts. Note: Pipe threads use different sizing. Some of the tubes and lines in cars use pipe thread sizes. See pipes.

Tap Drill Sizes

Drill Sizes:

Wrench Sizes: Metric:

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Lubrication: links: Metal Properties Fastener Material | fastenal.com US & Metric Bolt Torque by Grade Screw Finder at BobbyDyer.com ANSI External Screw Threads Size Tolerances Chart - Engineers Edge Technical Reference Guide | Fastenal.com BOLT SPECIFICATIONS | Spirol.com Metric Bolt Properties, Grades, and Strength Organizing Nuts, Bolts and Washers - Addtoit Screw Information at search.com Screwtypes at lara.com Fastener Material Chart at CenturyPerformance.com Metric Bolt Properties Grade, Strength Shear force - Wikipedia, the free encyclopedia Proof Loads at FullerMetric.com Strength at AtlanticFasteners.com ASTM, SAE AND ISO grade markings and mechanical properties for steel fasteners at AmericanFastener.com SAE Standards for Bolts CD Stud Fasteners Specifications at SunBeltWelding Tap Drill Sizes Corrosion Resistant Bolts at contractors-sources.com Aircraft Hardware Automotive Racing Products (ARP)- Bolts Stainles Steel fasteners with specs for Aluminum, Titanium also at ssina.com Fastener and Screw / Bolt Design, Formula and Calculation at Engineers Edge Strength Properties of Metals at EngineersEdge.com The Tempering of Martensite Types of bolts and screw heads. Fastener types. Fasteners 101 Home Depot Special Order Fasteners at CrownBolt.com

"The Nuts and Bolts of Bolting" by Joseph C. Dille

Gardner-Westcott is a bolt manufacturer.

Pozidriv™ is a trademark of European Industrial Services Ltd.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||