Home & Garden

Home & Garden

Painting

Contact

Painting

Contact

Don's Home

Home & Garden

Home & Garden

Painting

Contact

Painting

Contact

|

Guidelines: Stains Over 70° Wipe off immediately

The emphasis of this page is outdoor wood siding, decks and furniture, but it includes some general guidelines e.g. oil paint vs latex (Water based).

Outdoor wood provides unique challenges becase of potential water (rain & snow) and Sun (UV light) damage.

Stains | Oil vs Latex | Tips

Stains:

Choices are Semi-transparent vs. Opaque (solid) and Oil vs. Latex

Oil vs Latex:

Latex: Consist of a pigment and binder with water used as carrier

Life span of different kinds of finishes: at the USFS Forest Products Laboratory (FPL)

| Water repellents | 6-12 months |

| Clear water-repellent preservatives | 1-2 years |

| Pigmented water-repellent preservatives | 2-3 years |

| Varnish | 2-3 years |

| Solid-color stains | 3-7 years |

| Semitransparent stains | 3-8 years |

| Paints | 7-10 years |

About:

Wood Finishes:

Comments at WoodenBoat.com Forum

David G wrote:

- Most wood finishes are various proportions of 3 components: resin, oil, solvent. A pure oil finish, like tung oil, or linseed oil could be 0% resin, 100% oil, and 0% solvent. A spar varnish has some of each component. The higher the resin content... the faster the film build. The higher the solvent content... the cheaper it is.

- Resins can range from old-school, like copal or amber, to phenolic, alkyd, and polyurethane.

- Oils might be linseed, soy, tung, and safflower.

- Solvents can be anything from water to turpentine, to mineral spirits, to lacquer thinner, to xylene, MEK, etc.

So - in terms of terminology - the Watco and Daly's SeaFin teak oils would be called oil/varnish blends, but not wiping varnishes (as I said earlier - not enough resin content).

So - to the OP - I'd say the same as others have. Decide between 3 strategies.

- First - Leave it bare. It'll weather to a nice dove-gray patina, and be the lowest maintainance approach.

- Second - Use oil. The two most common choices are boiled linseed oil and tung oil.

It's easy to apply and easy to touch up. It requires discipline. If you don't refresh the finish religiously - before it appears to need it... you'll have made yourself a mess you'll have to clean up.

- Third - A film finish. Most common is spar varnish. This is what I'd recommend if you decline the bare teak look.

The oil/varnish blends will build a film - just like varnish - they'll just take more coats to do it. If you should go that route - the Daly's product has better quality oils and resins, and a lower proportion of solvents. The Watco Teak Oil I've seen used did not hold up over time.

| BLO | Pure Tung oilHas added metal compounds |

|---|---|

| Dries faster (because of added compounds) | Dries more slowly |

| Will yellow with age | Doesn't yellow |

| Can go rancid | Nope |

| Can mildew | Nope |

| Nope | Has waterproofing qualities |

| Nope | Retains some flexibility when hardened |

| Cheaper | More expensive |

Tung oil is the preferred choice by skilled craftsmen. It penetrates deep into the pores of the wood, forming a bond from within and actually becoming a part of the wood.

While wood stain provides a bit of protection against various hazards, a coat of tung oil on a wood surface can help reduce damage caused by water, abrasions, acids, mold, and mildew.

Applying tung oil over an oil-based wood finish is not advisable. This is because the oil stain fills the pores of the wood and prevents the tung oil from then absorbing. However, you can still mix oil-based stain into the tung oil and then apply it all at once.

Applying tung oil finishes over a water-based stain confers extra protection and optimal durability.

Applying Tung Oil to Stained Wood for the Right Look

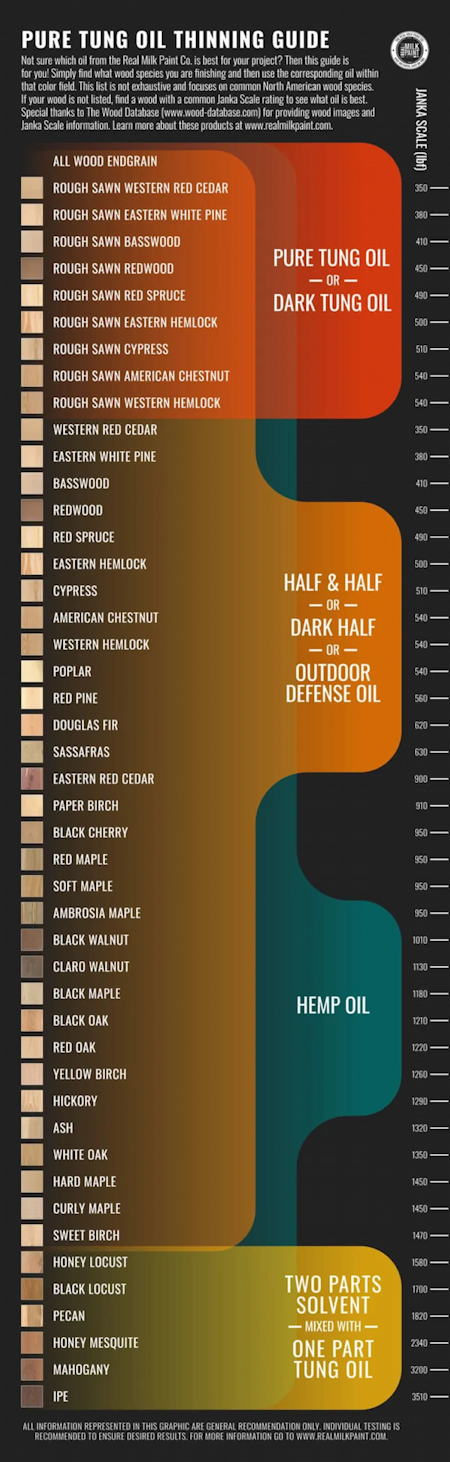

Tung oil should be thinned on harder woods, e.g. mahogany.

When thinning tung oil, it is important to use an oil-based solvent such as mineral spirits, citrus solvent, odorless mineral spirits, turpentine, or VM&P naphtha. Avoid using VOC compliant or 'green' solvents as they will not mix well with tung oil.

Here are some products for thinning tung oil:

Spar varnish is a type of varnish that is specifically designed to protect wood from the elements, including rain, snow, sun, and wind. It is made with special resins and oils that make it more durable and flexible than other types of varnish, which allows it to withstand the expansion and contraction of wood as it is exposed to different weather conditions.

Polyurethane is also a durable finish, but it is not as well-suited for outdoor use as spar varnish. Polyurethane is more brittle than spar varnish, and it can be more susceptible to cracking and peeling when exposed to the elements. Additionally, polyurethane can yellow over time, which can be less desirable for outdoor furniture.

Here is a table that summarizes the key differences between spar varnish and polyurethane:

| Feature | Spar varnish | Polyurethane |

|---|---|---|

| Durability | More durable, especially outdoors | Durable, but less so than spar varnish |

| Flexibility | More flexible, which allows it to withstand the expansion and contraction of wood | Less flexible, which makes it more susceptible to cracking and peeling |

| UV resistance | Excellent UV resistance | Good UV resistance, but not as good as spar varnish |

| Yellowing | Less yellowing over time | More yellowing over time |

How To Treat Wood For Outdoor Use

See also: Difference Between Spar Varnish and Regular Varnish? | Wood Whisperer

Components: Oils – Linseed Oil or Tung Oil Resins – Alkyd, Phenolic, or Polyurethane Solvents – Mineral Spirits, Naptha, or Paint ThinnerHigh Quality spar varnish finishes:

Epifanes Formulated with tung oil, phenolic and alkyd resins resulting in a finish that has superior flow, gloss, durability, and exceptional longevity.

Epifanes Formulated with tung oil, phenolic and alkyd resins resulting in a finish that has superior flow, gloss, durability, and exceptional longevity.

Here are some tips for applying spar varnish to outdoor furniture:

Can you put spar varnish over tung oil on redwood. In fact, this is a common finishing schedule for redwood furniture and other outdoor projects.

To apply spar varnish over tung oil, simply make sure that the tung oil has completely cured before applying the varnish. This can take several weeks, so be patient. Once the tung oil is cured, sand the wood lightly to create a smooth surface.

Here are some tips for applying spar varnish over tung oil on redwood:

There is no such thing as water base. Water is a solvent for water-borne coatings. Water-borne finishes can contain oils, alkyd resins, epoxy resins, polyurethane resins, etc. These are the various kinds of binders. They all have different properties. To apply water base to them as a means of explaining their values is not only misleading it is stupid.Water reducible coatings that use latex resin as the vehicle (pigment carrier) may wet-crock (soften when wet) and rub off when you walk on them when wet.

See removing mold, mildew and alge.

Semi Transparent vs. Opaque (solid-color):

Exterior stains for clapboard and cedar-shake siding come in solid and semitransparent formulations. Opaque (solid-color) finishes look almost paintlike, covering the wood completely so the grain doesn't show. Semitransparent stains add color to the wood but let the grain show. Either type soaks into the wood, leaving a flat dull, finish.

Opaque finishes tend to last longer.

They also come in Oil and Latex.

At Finishes for Exterior Wood Surfaces: Options For The Painting Contractor on Historic HomeWorks.com web site they say:

Semi-transparent stains are probably the most popular and widely used of all the natural finishes. These products are available in a wide variety of colors but, like the other natural finishes, they are penetrating and, thus, do not fail by blistering, flaking, or peeling in the way that film-forming coatings may fail.

Solid body, solid color, or solid hide stains are much more similar in nature to paint systems than they are to semi-transparent stains. These products, whether water-based acrylics or oiled-based solvent-borne systems, form a coating on the wood surface, hiding most of the wood and usually dramatically altering the color of the natural grain and character of the wood. When applied over extractive rich woods such as redwood and cedar, acrylic solid color stains should be applied over a top quality oil- or alkyd-based primer specifically formulated for extractive rich woods. As with the other finishes previously discussed, where the manufacturers' formulations allow, a minimum of two coats should be applied for the best performance. Solid body stains may need re-application every five to seven years. Coatings such as these are not recommended for decks and walking surfaces.

How To Treat Wood For Outdoor Use | Proline says,

1. Apply an outdoor-rated finish: polyurethane, lacquer, varnish, or epoxy.

Most wood finishes last several years. They are not permanent but definitely increase longevity. After you treat wood once, the process will go much quicker in the future!

Varathane (now part of Rust-Oleum) and Minwax make polyurethane, they have fast drying version which is thinner but may have to be applied more often or in multiple coats.

2. Seal with linseed oil or tung oil.

See linseed oil vs tung oil.

3.Use an all-in-one stain-sealant combo.

Comparison of different clear finishes:

wax, shellac, Nitrocellulose lacquer, Conversion Varnish, Alkyd varnish, Polyurethane varnish, Linseed oil, Tung oil, Water-based polyurethane, oil-varnish mixes.

See: Timber Finishes - Interior | WoodSolutions.com.au

Latex over Oil and vice-versa:

You cannot apply latex paint over an oil base because it will not adhere properly and will peel or scratch off easily. In general, you should always put an oil-based paint over an oil base, and water-based paint over a water base. Although you can paint oil over latex, over time it will crack. The only exception to these rules is alkyd primer. Most alkyd primers are formulated to go under both oil and water bases.

In Latex Paints Over Oil-Based at Paint Quality Institute they say:

The rule of thumb is that, given proper surface preparation, for exterior use you can apply quality latex paints over oil-based, but not the reverse. However, if you have many layers of oil based paint, stick to using oil on oil.

Another article stated:

Up until recent years, painting latex over oil was taboo since it had no adhesion properties designed to make it stick to oil surfaces, which meant that you could literally take it off using a fingernail or even just attempting to wash the wall.

If you can paint latex over oil based primer, why can't you paint latex over oil based paint?

The reason why latex can be painted over oil primers is because oil primers are formulated differently than oil finish products. Oil primers actually have a lot of flexibility, allowing them to move, much like latex. Oil paints are much too hard when they dry, not allowing for much flexibility at all.

We would not recommend using a latex primer to be coated with an oil finish in most exterior cases due to the difference in flexibility, but an oil/alkyd primer under latex finish paint is a good method.

For interior surfaces once they are properly prepared and primed it is not an issue to apply oil over latex or latex over oil. Modern primers will accept either over either. The relatively new High Performance interior acrylic paints claim to be the self-priming super stars of interior trim paint.

Application:

Brush application is usually superior to roller, spray, or

painting-pad application, especially for the first coat. Professional painters can

usually spray paint and obtain good performance.

The main reason professional painters spray paint on these days is to save costs on both labor and materials. It would probably be too expensive for you to pay professionals to hand roll or brush an entire exterior today.

However, a spray is a surface application only and does not fill cracks, or seal most rough-sawn wood or stucco properly. That is why you should always backroll and brush after most spray applications, to enhance the look and achieve a longer lasting paint job. A painter who does not take this extra step may charge a little less, but you are right that in most cases, a spray-only paint job simply will not hold up as long or well.

Spray-only applications are appropriate on smooth surfaces where rollers or brushes will leave undesirable finishes. These would include smooth lap siding, garage doors, exterior metal doors and some gutters. In these cases, it's recommended to spray on a good quality enamel exterior finish with a fine orifice tipped sprayer to achieve professional factory-finished results.

The Wagner Power Roller speeds up painting, but it is a bear to clean. If you only have a moderate sized area to paint it may not be worth it.

Natural bristle brushes should be used for oil-based paints and stains, and not for water-based or latex products because they get limp.

the topcoat should go on within two weeks of the primer. If you wait too long, the mechanical bond between the two won't be as strong because the surface texture of the primer breaks down. And if two topcoats are used (recommended for new construction), the second should go on within two weeks of the first.

Temperature:

Solid stains can be applied as long as the temperature is above 35° and dry for 24 hours.

45-50° is recommended for water based solid stains.

Applying deck stain when temperatures are too cold can affect the curing process of the stain. Applying deck stain when temperatures are too hot can cause the stain to evaporate and dry too quickly. In both cases, the stain’s performance can be jeopardized.

Latex semi-transparent stains do not penetrate the wood surface, but they are easy to apply and less likely to form lap marks. These stains are film-forming and are not as durable as oil-based stains.

Unlike paint, a solid-color stain may leave lap marks.

Lap marks can be prevented by staining continuous lengths. This method prevents the front edge of the stained area from drying before a logical stopping place is reached.

Exterior-Painting-Techniques at servicemagic.com

Exterior Painting at Philpott Evitt Building Centre in BC

Products:

See Deck Paints in Products

Behr premium solid color waterproofing stain and sealer product detail

Links:

Finishing Outdoor Furniture

Refinishing Teak | here

How To Treat Wood For Outdoor Use

Deck Paints and Resurfacers

Preparation and Priming

Refinishing Teak

Why is my paint peeling at This Old House

Advantages Of Oil VS. Latex at PaintingYourHouse.info

Painting and Painting exterior wood - oil vs latex at Al's Home Improvement center.

Paint, Stain, Varnish, or Preservative? at the USFS Forest Products Laboratory (FPL)

Finishes at CarolinaColortones.

Finishing Western Red Cedar Siding

Before you Stain your Wood Siding at True Value Projects

20 most frequently asked questions at Morwear.com

Painting cedar siding and cedar siding maintenance and care at cedar-siding.org

13 Painting Secrets the Pros Won’t Tell You

All About Exterior Paint and Stain at paint-and-supplies.hardwarestore.com

Ladders